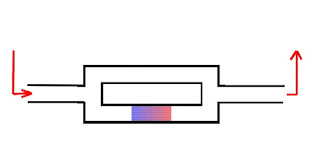

From the information found, it first appears in Kees de Blok's study that he integrates the loop and bypass engines:

Bypasses In The Loop Thermoacoustic Engine (BITL TE) the micro-sized thermoacoustic engine.

It is not known how competitive the BITL machine is compared to the wide generator loop machine on a large scale, but as a micro-sized thermoacoustic machine it is definitely worth considering!

In micro size, external heat exchange is not a problem, however, the design of units with a wide internal heat exchanger is almost impossible and very expensive. In the field of micro-sized thermoacoustic generators, the competitiveness of BITL machines would definitely be worth investigating more deeply!

I think the membrane (diaphragm) thermoacoustic engines are the most powerful, because from the quantity moved of the gas by power piston and from its energy goes more through the regenerator than with the Tashe engine.

But how to make a membrane out of gas? The most similar can be done by looping to create a traveling wave in the bypass.

Traditional thermoacoustic loop engine is simple, but it doesn't like the long regenerator. The regenerator strangles the gas pistons a lot because gas pistons have small weight and momentum. If the gas piston is too long, the resistance of the pipe is huge. Have you ever tried to blow through pipes of different lengths? You will be amazed at how hard it is! The regenerator is widened and made thinner how it not be strangled the gas pistons. This widening also creates a softer suspension space into which the gas piston can penetrate with greater momentum, and the bigger regenerator surface alsowill give the engine more power . A thin regenerator has a higher heat loss at high temperatures because heat passes through it, and in small size very cumbersome build because the heating or cooling fluid has to be introduced into the engine and expensive.

If we want a longer regenerator and shorter tubes, then instead of a gas piston (resonator) we can use a water piston, but it will be too slow, the power of the engine will be less, or we can use membranes with mass, but they must be durable and tuned, or solid pistons which must be very accurate but these make construction difficult also. These are not as simple as they seem.

In the bypass engine, the regenerator does not choke the piston because it does not be in its way, but at the bouncing goes a part of the gas to through the regenerator, where the gas can expand or contract. Therefore, a longer regenerator also works. The bypass engines are more efficient.

With these engines developments perhaps possible to combine the advantages of the loop (with more regnerators) and bypass engine. The goal is a motor with an easier plannable, simpler heat exchanger, pressurized turbine generator, without a membrane which is easy and inexpensive to build at home. The Gedeon streaming can be stoped without a membrane also.

https://drive.google.com/file/d/1BAG_oi_PPum9c9fTpPXTStRNdl2P0wgA/view?usp=sharing

https://drive.google.com/file/d/11oF2v4bdepgYCNSSgVW-1Q4jmKZW-2eh/view?usp=sharing

https://drive.google.com/file/d/1Yu5FdeHdhkyM7hE13RFGQn1cKRLS_BrF/view?usp=sharing

https://drive.google.com/file/d/1V1kyskDh1prwNk79JHKovtTJdkn_M5nP/view

https://drive.google.com/file/d/1HX-8NUsaNRfFGQ_t9d-jdQmpniARcKaQ/view?usp=sharing

https://drive.google.com/file/d/1fLKTBYJ1GDXp9v3vtvDf0gGN5ftB--ZA/view?usp=sharing

https://drive.google.com/file/d/1_3dZffIvpev0tkCDrcuwREapzfbh1v-E/view?usp=sharing

Some basic rules:

-Works with the loop resonator if the bypass is longer, shorter, or the same length as the regenerator branch.

-works without a loop resonator if the bypass is as long or shorter than the regenerator branch.

- If the regenerator branch is longer, it works better.

-If the bypass is the same length as the regenerator, but the membrane facing the atmosphere is in the middle, it can be stoped.

-If the regenerator branch is longer, the membrane facing the atmosphere can be captured on the cold side, very weak on the warm side.

-If the bypass is longer than the regenerator branch, the membrane facing the atmosphere on the hot side cannot be stoped, but there is no max. force in the loop, but the force is on the membrane.

-Even stronger if the regenerator branch is longer and the regenerator branch is almost on the edge, but vice versa, leaving a thermal buffer tube (TBT) part as well. In this case is needed loop resonator and the bypass can't be too short.

-If four external resonators are used, if one is clamped, the machine will stop.

-If one external resonator is used, if it is clamped, the machine will stop.

-If the loop is very short, it will only work with a dense regenerator.

If the gas could flow freely in the empty loop, couldn't it be completely one direction and we can use a conventional turbine?

Summary:

In the case of thermoacoustic machines, temperature change is possible in five ways.

1. We apply with the heat exchange a stack. The stack works with a time delay.

- standing wave engines

2. Traveling wave, alpha type motion.

-Aster loop engine

3. A resonator (power piston) is connected to the machine, which pushes the bypass gas piston, and this goes through on the regenerator with its momentum like a displacer.

-TASHE

4. The loop is the power piston, and the gas oscillates back and forth in it, it heats up and cools, and expands and contracts. A thin tube is connected to the loop. On this not only goes through on it the pressure , acts a bit like a Manson machine-like but also its has a momentum and reverses the direction of the flow into the loop.

-Metronome

-Fuydine machines

5. With active membrane. Membrane is used similarly as a stirling displacer.

Often these processes are not sharply separated, those are present somewhat mixed.

More:

https://drive.google.com/file/d/13fImdv1X5GFknbqgAcSaKBoWFkHF8iCJ/view?usp=sharing